Understanding CNC Lathe Parts Manufacturing in China

The landscape of manufacturing has evolved dramatically over the last few decades, with China emerging as a powerhouse in the field, particularly in the area of cnc lathe parts manufacturing. As businesses look for reliable partners for their precision engineering needs, understanding the dynamics of CNC lathe manufacturing in China becomes crucial for success.

The Rise of CNC Technology

CNC (Computer Numerical Control) technology has revolutionized the manufacturing process. It enables the automation of machine tools through the use of predetermined sequences. This technology offers unparalleled precision, making it an ideal choice for producing complex parts like those found in automotive, aerospace, and industrial applications.

Why Choose CNC Lathe Parts Manufacturers in China?

When it comes to sourcing CNC lathe parts, China has established itself as a leader for several reasons:

- Cost-Effectiveness: China offers competitive pricing due to lower labor costs and economies of scale. This results in significant savings for companies that source from Chinese manufacturers.

- Quality Assurance: Many Chinese manufacturers adhere to international quality standards, often obtaining certifications such as ISO 9001, ensuring that the parts meet global requirements.

- Diverse Capabilities: From small batch production to large-scale manufacturing, Chinese companies can accommodate various project sizes and complexities.

- Innovative Solutions: Many manufacturers invest heavily in research and development, thus providing state-of-the-art solutions that keep pace with global technological advancements.

- Timely Delivery: With refined logistics and manufacturing processes, manufacturers in China can often promise shorter lead times.

The Manufacturing Process of CNC Lathe Parts

The production of cnc lathe parts in China involves several key stages:

1. Design and Prototyping

The first step in manufacturing CNC parts is the design phase. Engineers use Computer-Aided Design (CAD) software to create detailed blueprints of the parts. Once the designs are finalized, prototypes may be produced to test functionality and fit.

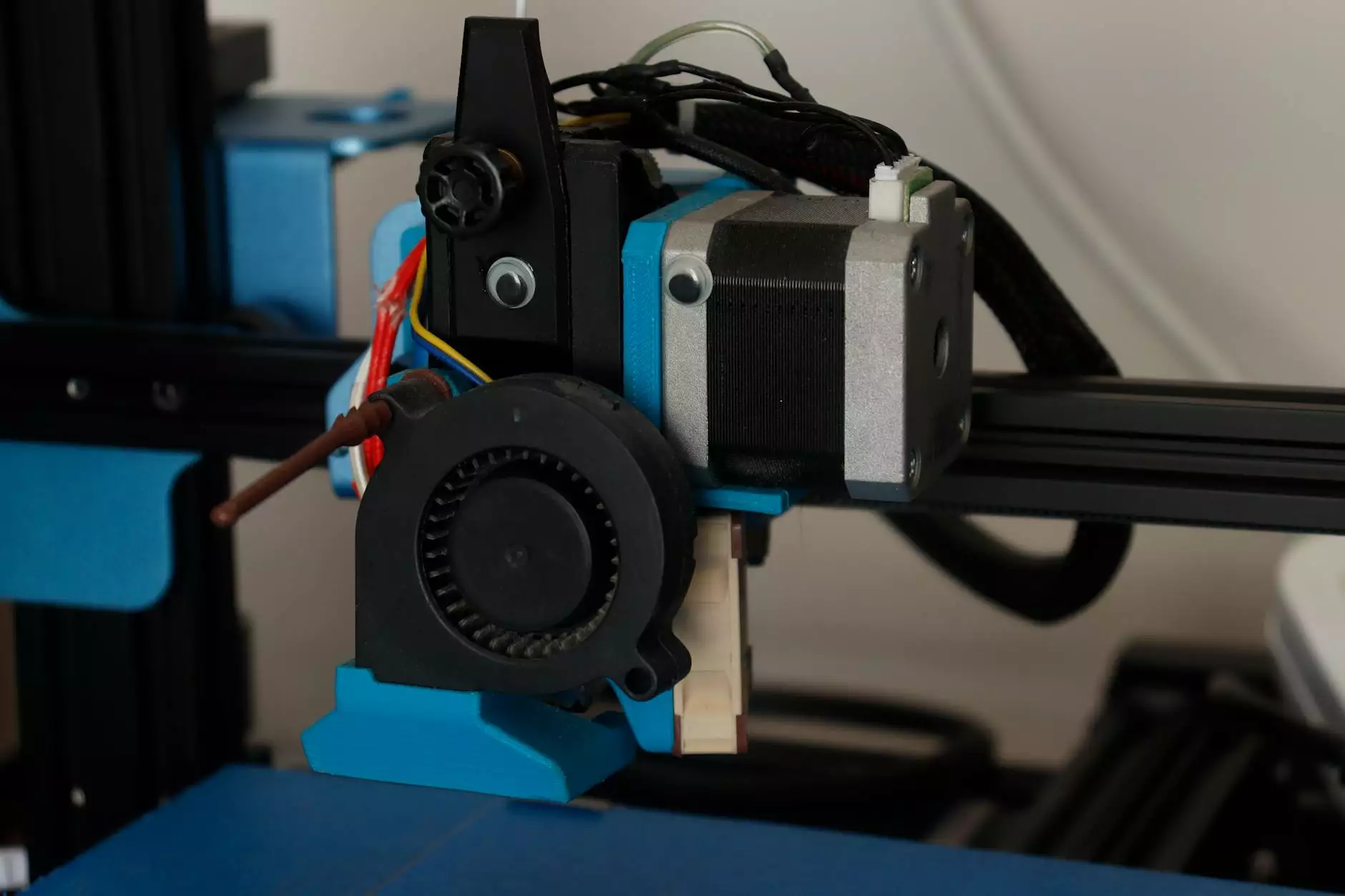

2. Machining

Using CNC machines, manufacturers can precisely cut, drill, and shape materials such as metal, plastic, and composites. CNC lathes are particularly adept at creating rotational parts and features.

3. Finishing

Once the parts are machined, they often require finishing processes. This can include sanding, polishing, coating, or anodizing to enhance appearance and durability.

4. Quality Control

After production, parts undergo rigorous quality control procedures. This includes dimensional inspection, functional testing, and adherence to specification reviews to guarantee the quality of each component.

Common Applications of CNC Lathe Parts

The parts manufactured using CNC lathes are utilized across various industries:

- Automotive: From engine components to transmission parts, CNC lathe parts are essential for vehicle performance and safety.

- Aerospace: Precision-made components are critical for the aerospace industry, where safety and reliability are paramount.

- Medical Devices: CNC lathes are used to manufacture intricate components for medical equipment, ensuring they meet strict regulatory standards.

- Industrial Machinery: CNC lathe parts play a vital role in the efficient functioning of machinery used in various manufacturing processes.

Finding the Right CNC Lathe Parts Manufacturer in China

Choosing the right partner for CNC lathe manufacturing is crucial for success. Here are some steps to consider:

1. Research and Reviews

Start your search by evaluating potential manufacturers based on their reputation. Look for reviews and testimonials from other businesses to gauge their reliability.

2. Request Samples

Before committing to a large order, requesting samples can help verify the quality standards of the manufacturer.

3. Evaluate Capabilities

Make sure the manufacturer has the necessary machinery, technology, and expertise to handle your specific requirements.

4. Communication

Clear and consistent communication is vital. Ensure that the manufacturer understands your project scope and can provide timely updates.

Potential Challenges of Sourcing from China

While there are numerous benefits to sourcing CNC lathe parts from Chinese manufacturers, there are challenges as well. Being aware of these can help mitigate risks:

- Language Barriers: Different languages can sometimes lead to misunderstandings. Ensure you have bilingual support if necessary.

- Quality Variability: Not all manufacturers offer the same quality. Conduct thorough checks or consider third-party inspection services.

- Logistical Issues: Shipping and customs can delay timelines. Plan ahead to accommodate potential logistical challenges.

- Cultural Differences: Understanding business practices and negotiation styles is key to building a successful partnership.

Conclusion

In summary, sourcing cnc lathe parts from China can be a smart move for businesses looking for quality and cost-effective solutions. By grasping the manufacturing process, recognizing applications, and navigating potential challenges, businesses can build a productive and beneficial relationship with Chinese CNC lathe part manufacturers.

For high-quality CNC machining solutions, consider partnering with reputable manufacturers like DeepMould.net, who specialize in precision metal fabrication and provide extensive capabilities to meet your specific needs.

china cnc lathe parts manufacturers